Creating an earthen pond can be very rewarding, whether you’re building a reservoir, farm pond, canal, koi pond, stock pond, or any earthen pond. An impermeable water barrier to prevent ground loss is essential to make sure your pond lasts. When it comes to pond lining, natural sodium bentonite offers a highly effective and environmentally friendly solution that will last indefinitely.

Sodium bentonite is a naturally occurring clay containing weathered volcanic ash. It is a powerful adsorbent which swells and expands when hydrated, creating a dense, impermeable layer. This expansion makes sodium bentonite ideal for leak prevention and pond sealing, even for the most porous or sandy soils.

Benefits of Pond Sealing with Sodium Bentonite

Most pond sealing uses either a compacted clay liner (CCL) of sodium bentonite or geo-synthetic clay liners (GCLs- manufactured products consisting of a layer of clay sandwiched between synthetic materials). Let’s look at some of the benefits of using compacted sodium bentonite over poly liners for sealing ponds.

Sodium Bentonite is Eco-Friendly and Non-Toxic

A natural, non-toxic formula is one of the most significant advantages of using sodium bentonite. It integrates seamlessly into the native soil and, unlike chemical sealants, does not introduce any harmful substances in your pond’s ecosystem. Sodium bentonite eliminates the risk of microplastic contamination in your soil and is a safer choice over GCLs. It poses no risks to plants, soil health, fish, and other wildlife, ensuring that your pond remains a healthy and thriving habitat. Natural bentonite harvesting also has a much smaller carbon footprint than poly liners.

Sodium Bentonite is Durable and Sustainable

Sodium bentonite is extremely durable under different soil conditions, landscapes, and climates. Once it is applied and properly hydrated, it forms a resilient seal that withstands environmental and seasonal changes without the need for ongoing maintenance or repairs. Because it naturally rehydrates, compacted sodium bentonite can self-repair and heal small cracks or holes that may develop over the years.

In contrast, even the toughest GCLs can degrade over time, especially when exposed to UV radiation, chemicals, or physical damage. When poly liner integrity is compromised, repairs can be costly and labor intensive.

Sodium Bentonite is Versatile and Adaptable

Sodium bentonite can be compacted to line and seal a wide range of pond shapes and sizes. Its ability to expand and fill gaps makes it the perfect choice for irregular contours and uneven surfaces for any soil type. Compacted bentonite is particularly beneficial during dry spells or areas with fluctuating water availability.

GCLs are much less adaptable to irregular shapes and their costs increase with customization.

Sodium Bentonite is Affordable and Easy to Install

Compared to synthetic liners, sodium bentonite is a much more straightforward and affordable option both for materials and labor expenses. Bentonite doesn’t require specialized equipment or installation experts. Plus, bentonite’s longevity means you will save more in the long run on future repairs and reinstallations.

GCL installation requires complex and precise placement with hired professionals.

How Much Sodium Bentonite Do I Need to Seal a Pond?

Your application rates will depend on a few factors:

- Pond size

- Soil type (conduct a soil composition test to determine application rate)

- Application method used (pure blanket or mixed blanket; see below)

There are 2 types of soil tests to help you know how much bentonite you need to seal your pond:

- Lab soil composition test: for the most accurate soil composition results, you can send 20 lbs of your soil to our lab or a lab of your choice for around a $400 fee.

DIY Bucket Test: self testing is less accurate, so be sure to factor in a buffer margin of error. Watch our easy how-to video to conduct your own soil bucket test.

Pure Blanket Method

The pure blanket method uses a layer of sodium bentonite over the top of your native soil, without mixing.

Step 1: Prepare the water bed

- Excavate the pond and smooth the surface as much as possible to make PondSeal application easier. Be sure that the dam side is higher in elevation than the inlet of the pond. Remember that smaller deeper ponds lose less water to evaporation than larger, shallow ponds

Step 2: Apply PondSeal

- Spread out PondSeal at 8 lbs per square foot. If you are applying with a rake, the un-compacted bentonite layer should be about 1 ½” thick. If using machinery (like a vibration roller), the compacted bentonite layer should be about 1” thick. Compaction is recommended after applying bentonite.

Step 3: Cover and Fill

- To protect the compacted PondSeal while refilling, cover with 6 inches to 1 foot of soil (more soil=more protection for your bentonite layer). Compact soil layer for a better seal. Fill the pond with a gentle flow of water to prevent erosion. Gently adding sand, gravel, and rock on top of the prepared soil where the water enters the pond can also help prevent erosion.

Mixed Blanket Method

The mixed blanket method creates a layer of blended sodium bentonite and native soil.

Step 1: Prepare the water bed

- Pre-till the native soil of the pond 3-5 inches deep. Make sure the surface area of the pond is smooth and free of debris (roots, sticks, vegetation, and rocks protruding through the native soil can cause leaks). The recommended slope of the pond is no more than a 1-3 foot slope (1 foot vertical drop for every 3 horizontal feet or 18.43 degree angle)

Step 2: Mix and apply PondSeal

- Evenly apply the recommended layer of PondSeal on top of the native soil (based on your lab test or bucket test results). Thoroughly mix the layer of PondSeal into the tilled native soil. Mix well to ensure an adequate seal. Lightly dampen while compacting the soil and PondSeal mixture. Note: mixing of the native soil and PondSeal can also be done off-site and applied to the pond area if necessary.

Step 3: Fill the pond

- Fill the pond with a gentle flow of water to prevent erosion of the new barrier of native soil and PondSeal. Gently added sand gravel and rock on top of the prepared soil where the water enters the pond can help prevent erosion.

Pond Sealing with Western Clay

Western Clay is proud to harvest all natural, American sodium bentonite from our volcanic deposit in central Utah. Our PondSeal® high swelling bentonite contains the very best nature has to offer from our land, to yours.

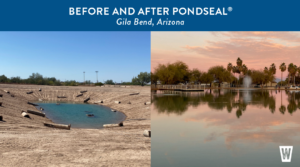

Check out what Western Clay was able to do for the town of Gila Bend, Arizona in our collaboration with the Arizona Deer Association. This rejuvenated park now holds an acre sized pond for fishing and family recreation, beautifying their land with a reliable water source that can be enjoyed for generations to come.

Call on Western Clay’s century of experience to build leak-free, sustainable ponds that protect both the environment and your investment.